Energy, Water and Materials

Although the completed CRL will help reduce Auckland’s carbon footprint, by reducing car use, its construction and operation consumes significant resources.

The project aims to reduce these impacts as much as possible in order to contribute to regional and national greenhouse gas emission reduction targets.

During the design phase, the team worked hard to optimise resource use for the lifetime of the CRL.

To measure success, total energy, water and materials use was estimated based on the early design ("base case") and the final "detailed design" was compared against it to quantify improvements introduced during the design phase.

Succeeding in projecting reductions for both construction and operation.

Construction is now entering its final stages, with the team continuing to maximise savings and track resource use on the remaining contracted work against projected improvements.

With design largely completed and construction well underway, the total reductions in the carbon footprint for stations and tunnels (Contract 3) are projected to be:

Embodied Carbon: 24,279 tCO2e (15.8%)

Construction energy: 6,684 tCO2e (19.2%)

Annual operational energy for the stations, tunnels and streetscape: 296 tCO2e (22.0%)

Details on the latest savings projected can be viewed in the 2022 CRL Health, Safety, Environment and Sustainability Report

In 2022, the CRL was awarded the Decarbonisation Outcome Award (projects over $20m) at the Building Nations 2050 Impact Awards recognising the project for exemplifying climate consciousness and the incorporation of decarbonisation into the project's full life-cycle.

Energy: Pūngao

Whole-of-Life footprint

CRL’s energy footprint is largely comprised of the diesel and electricity needed to construct and operate the stations and tunnels.

The challenge laid down for our main construction partner Link Alliance is to achieve a 25% energy carbon emission reduction compared to a business-as-usual Base Case.

The construction team are working hard to stay within this carbon budget. Energy is used during construction for everything from boring piles and transporting excavated spoil to heating water for workers’ tea and coffee.

A saving of just over 36,000 tCO2e of greenhouse gas emissions is currently projected. This is a 21.4% saving. Around 80% of this saving is expected to be achieved during the 100-year operational phase projected for the stations and tunnels.

The total savings projected for construction and operation, is equivalent to just over 42,000 economy class flights between Auckland and London.

The Chart below shows how these savings are expected to be achieved.

The graph below shows how emissions associated with energy use for Link Alliance contract 3 is tracking well below both the base case and detailed design projections.

Electric Multi-Service Vehicles (MSV)

Switching from diesel-power to electricity can reduce emissions by as much as 80 per cent. To make the most of these savings CRL used three electric MSVs with regenerative braking rather than the standard diesel.

These MSVs were used to deliver tunnel segments, equipment and people to the tunnel boring machine. The CRL tunnels were ideal for trying out this new technology, being relatively short with vehicles typically travelling downhill loaded (with 20 tonnes of segments) and uphill empty, thereby utilising regenerative braking for on-the-go charging.

The three electric MSVs saved the project over 200 tCO2e in emissions. With tunnelling completed the machines have been sent back to French manufacturer Metalliance with feedback on performance for use on other projects.

Water: Wai

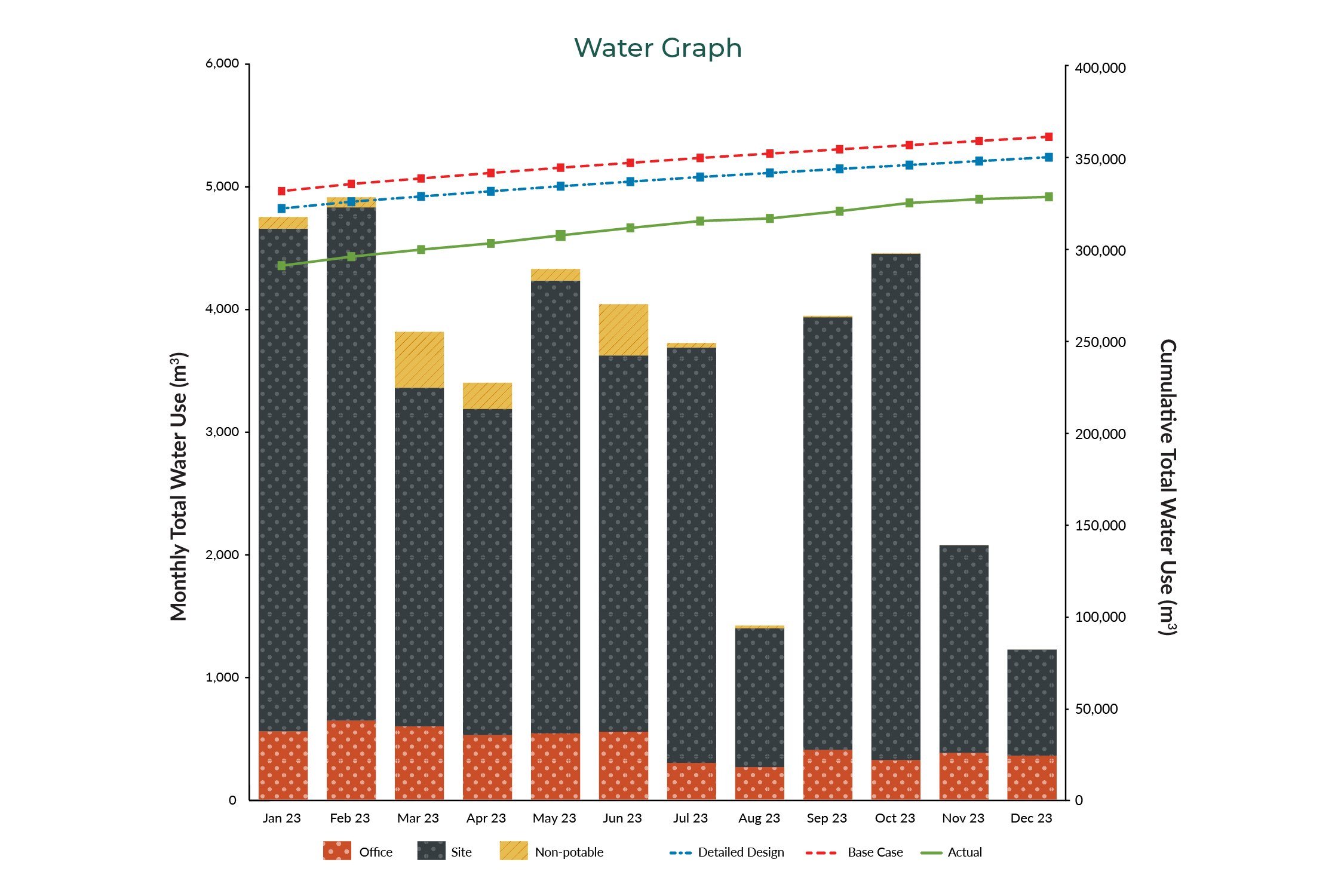

Saving water is a priority for CRL. Water use for both construction and operation of the CRL has been projected, and a 5% reduction target set.

Although the majority (82%) of the water used on CRL will be during its operation, construction is still expected to use more than 340 million litres, with the Tunnel Boring Machine being one of the largest users.

As well as designing the stations to be water efficient, a key approach has been reusing non-potable water (that is not of drinking quality) where possible.

Water Treatment Plants located on CRL sites process all water collected and ensure it can be safely discharged into the stormwater network. This non potable water and rainwater collected from roofs has been used for:

washing truck wheels before they leave site

cleaning the Tunnel Boring Machine conveyor belt, chute point and washing box

refilling the water carts that spray water on the ground to prevent dust being generated around the site and

other site cleaning.

Although total water use is tracking 14% below the original projection, the project has not been able to achieve the 5% water recycling hoped for at this stage, with 3.2% of all water used on site being from non-potable sources. Over 8,598,000 litres has been sourced from non-potable sources, equivalent to 38 households’ annual water use

Materials

Constructing the CRL requires significant quantities of materials - particularly concrete and steel - the production of which consumes valuable resources and produces greenhouse gases. The embodied carbon of these materials makes up half of the total carbon footprint over the project’s 100-year design life.

Efforts to minimise this embodied carbon have continued through from the design phase into construction where the team continues to look for ways to reduce these impacts.

The total reduction in the materials carbon footprint for each of the three main contracts is projected to be:

Contract 1: Embodied Carbon: 13,109 tCO2e (14%)

Contract 2: Embodied Carbon: 12,664 tCO2e (37%)

Contract 3: Embodied Carbon: 24,279 tCO2e (15.8%)

Main project partner Link Alliance’s (C3) target is to reduce embodied carbon by 15% against the base case design.

With the detailed design now complete, a 15.8% reduction is projected. Current progress is shown in the graph below. Approximately 55% of the footprint to date is from concrete, 31% from steel, 8% from cement for grouting and ground improvements and the remainder from aggregate, piping and asphalt and the transportation of materials to site.

Projected reductions result from:

Maximising cement replacement in concrete mixes

Redesign of the Karanga-a-Hape Station to remove the central mined walkway

Reducing the area of materials-intensive mined tunnels at Maungawhau Station

Change from piles to diaphragm walls (D-walls) across large parts of the project

Change from bottom-up to top-down construction across the project, reducing the need for temporary steel propping

Optimisation of the large retaining walls needed at the North Auckland Line connection.

FLY-ASH

A key construction-phase initiative has been reducing cement use in concrete. Cement has a high embodied carbon footprint of almost one tonne for every tonne used. Since construction started the team has maximised cement replacement with fly-ash, a waste product from coal-fired power stations, with a much lower embodied carbon.

This has allowed the main Link Alliance contract to eliminate 18,444 tCO2e, a 21.4% reduction to the end of 2022. Covid-19 impacts to the supply chain, especially international shipping, have made sourcing fly-ash more difficult, with the project having to ration its use at times, meaning the 26% reduction in footprint that was hoped for at the start of construction, may not be met.

50MM REINFORCING BAR

Earlier initiatives include the production of 50mm reinforcing bar for the first time in New Zealand.

Changing from contiguous piles to diaphragm walls underneath Britomart Station reduced steel use during the design phase and also reduced the time and cost of the station underpinning.

Due to the depth of the rock under the station (around 20m), using 40mm reinforcing bar (the largest size available in New Zealand at the time) would have resulted in reinforcing bar “congestion”, preventing the concrete properly flowing around the bars to form the diaphragm wall.

Fewer, but larger, bars were required. These had not been made previously in New Zealand. Contractor DSBJV worked with local manufacturer Pacific Steel in Otahuhu, which uses steel from the Glenbrook steel mill 40km east of Auckland, to fabricate New Zealand’s first 50mm reinforcing bar.

Besides improving constructability, using this larger diameter steel reduced the total weight of steel required by about 82 tonnes, lowering associated greenhouse gas emissions by just over 100 tCO2e.

It also reduced the transport emissions and costs associated with sourcing it offshore.